Star Trek replicator inches closer as NASA sends a 3D printer into space

It can't print a cake yet, but Made In Space's builder-bot should make life easier for astronauts

Star Trek’s replicator could make everything from pork chops to engine parts – now NASA’s taking a replicator of its own into space, in the form of a 3D printer.

Space component manufacturer Made In Space created the 3D printer, which will be sent to the International Space Station in 2014. While it can’t make a string of tasty sausages – yet – it will be able to print off tools, components and equipment on demand, having passed microgravity testing by NASA.

Star printer

“Humanity’s future ultimately depends on our ability to explore and occupy space,” Made in Space lead design engineer Mike Snyder explained. “The 3D printing technologies developed and tested during our Zero-G flights are a cornerstone to building that future.”

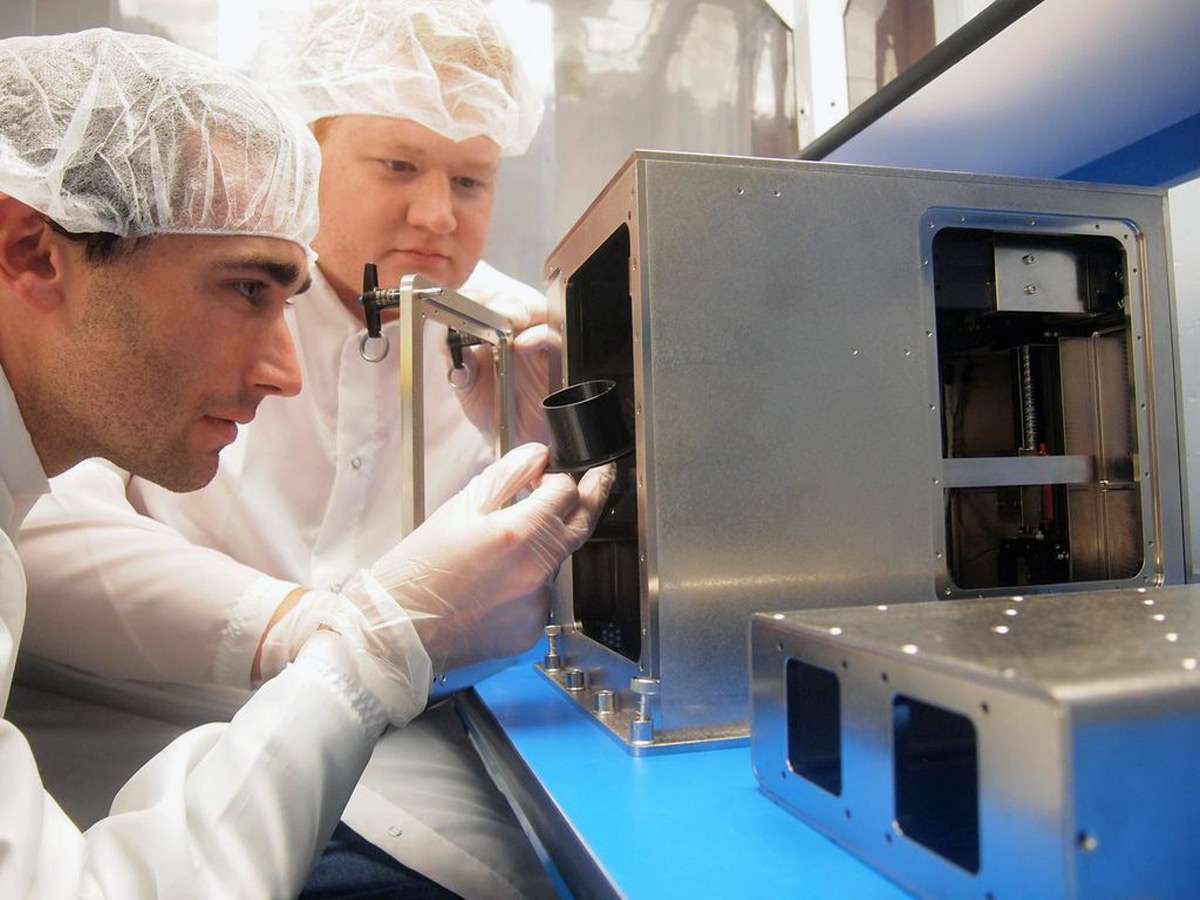

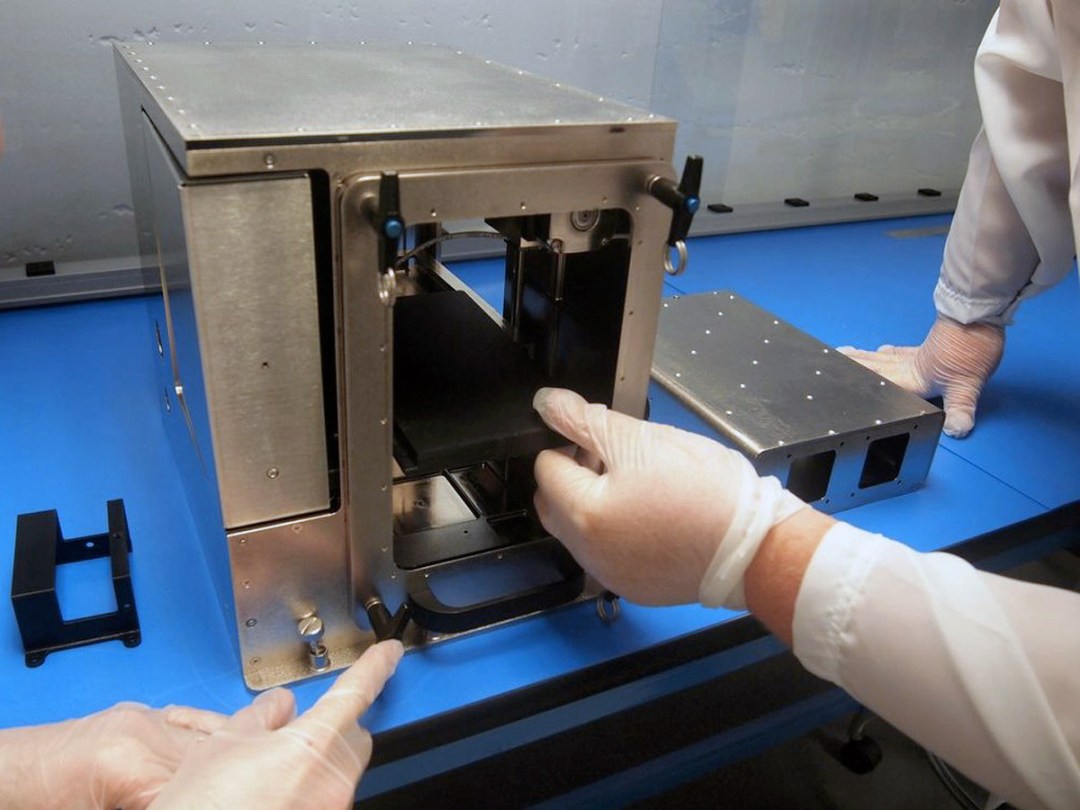

A lack of gravity makes 3D printing more difficult – so the Made In Space creation was built specifically to handle the challenge. It uses additive layer manufacturing (the type that builds up an object from extruded plastic ribbon), which happens inside a shoebox-sized metal enclosure with a glass front, allowing spacemen to check on the progress of their burgeoning plastic trinkets.

3D printing in space allows astronauts to fix problems on-the-fly as opposed to sitting by idly without being able to do a thing about it. Estimates say 30 per cent of all spare parts on the space station will be printable.

Not quite enough to print another space station, then, but perhaps in the future 3D printing will allow us to do just that? After all, the European Space Agency has already mooted the idea of 3D printing a Moon base.

[Made In Space via dezeen magazine]