Formlabs Form 1+ review

This is the next-gen of home 3D printing, but do the good looks, flashy lasers and magic goop equate to awesomeness?

Do you know your FDM from your SLA? Thought not, but these acronyms represent competing technologies that, in the world of 3D printing, have a rivalry of Hamilton vs Rosberg proportions.

The first stands for Fused Deposition Modelling – it’s the squirty plastic method of 3D printing employed by almost all of the 3D printers currently available to normal folk like you and I.

The second is laser-toting stereolithography – an industrial technology that’s actually been around since the late 80s, but is only now making an appearance in consumer printers with the Formlabs Form 1+. And it might just be the tech to set the 3D printing world alight.

Get your white coat on

So how does SLA work? It involves building up a print, layer by layer, using a laser to cure (harden) resin that is sensitive to UV light. It’s a well-honed industrial process that has always been restricted to much larger, more expensive commercial machines.

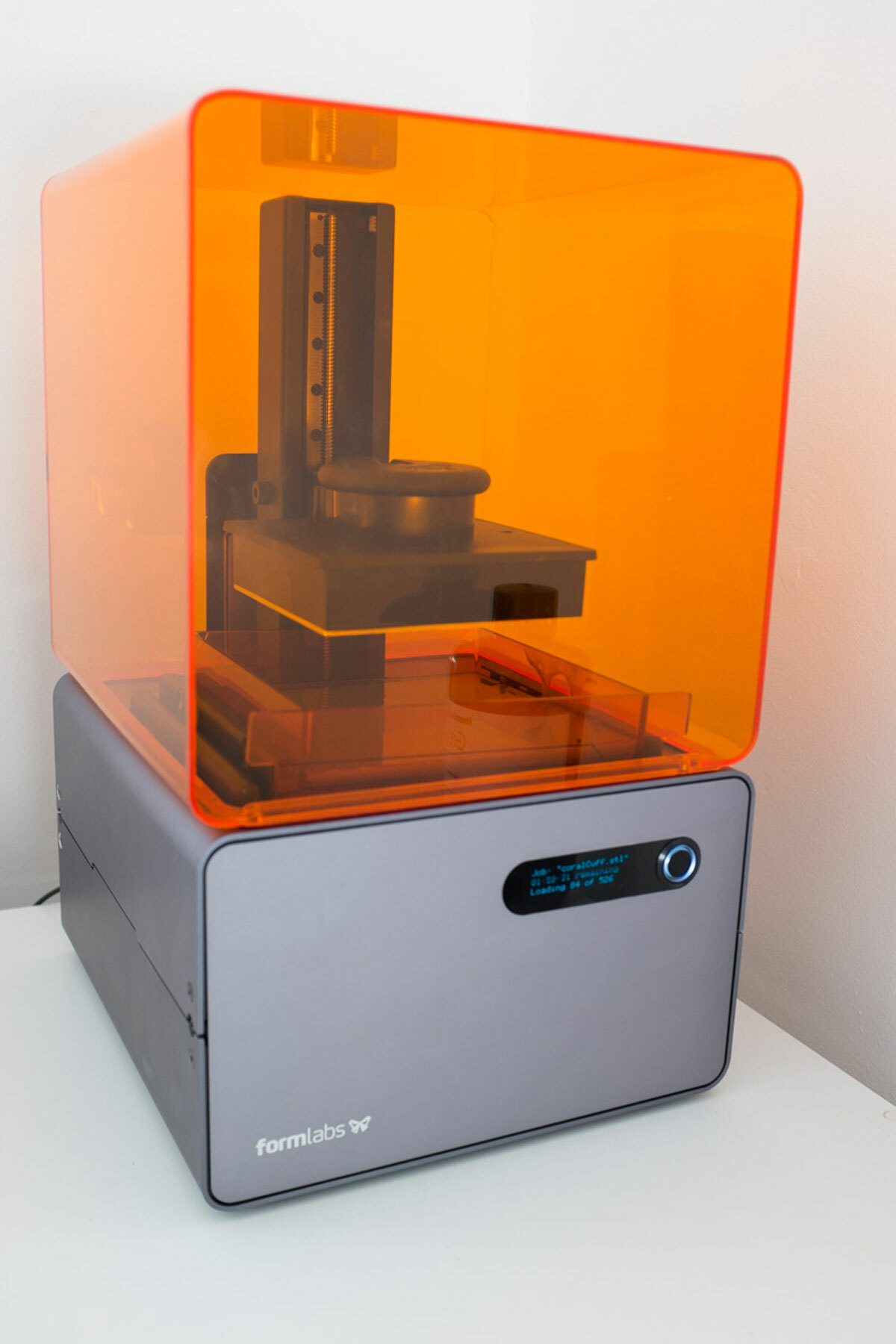

More than most other consumer 3D printers, even the very slick FDM-based CEL Robox, the Formlabs Form 1+ looks like a finely honed machine rather than a grown up garage project. In fact, it looks like it belongs in a high-end laboratory somewhere – the company name makes sense now.

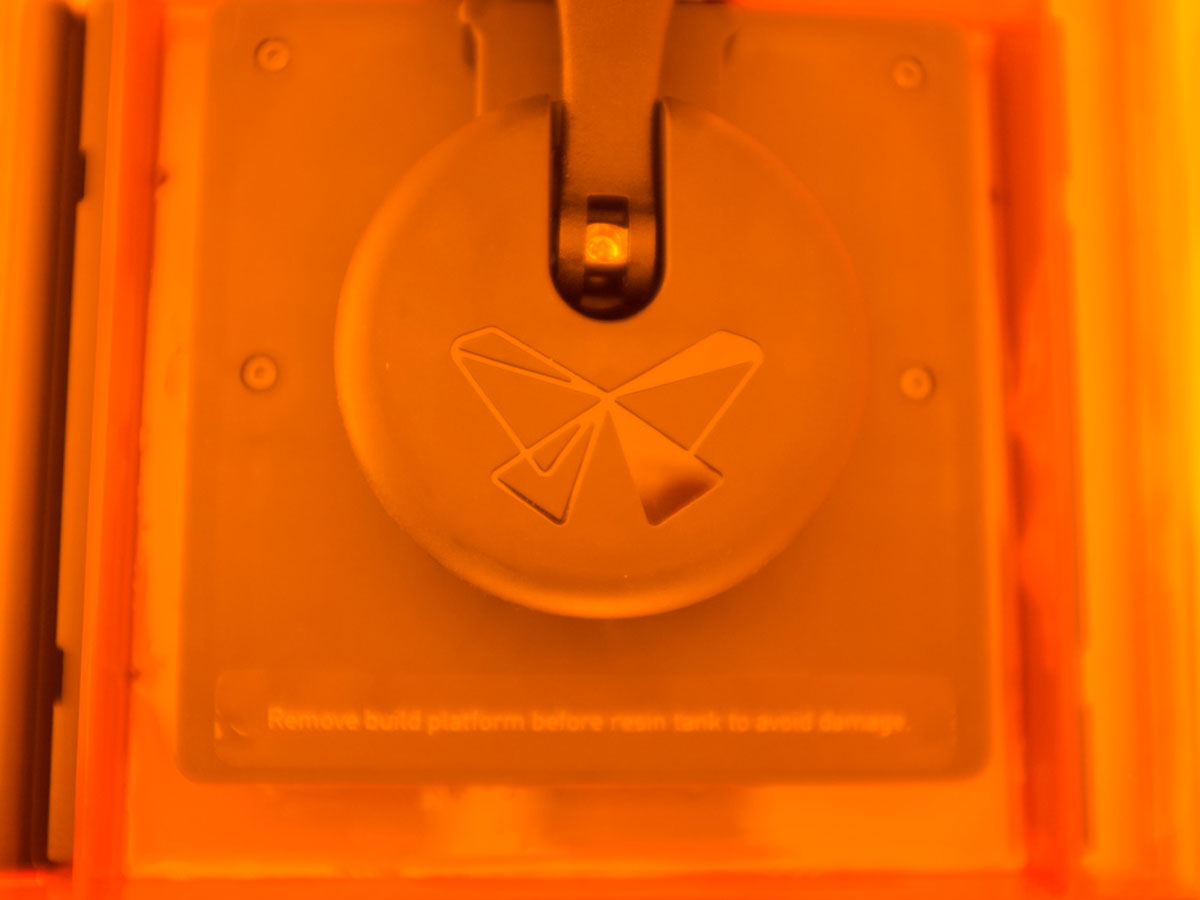

Getting started is part plug-and-play, part science experiment. The machine itself is hooked up to your computer via USB and controlled via the Formlabs PreForm application. But before you start printing you’ll have to load the resin tank and build platform. The resin tank is made of the same light-blocking orange acrylic as the Form 1+’s casing, and has a clear, silicone-coated base.

This is what the laser shines through, so keeping it free of fingerprints and dirt when sliding it into place is imperative. Once that’s done, it’s time to pull on the included rubber gloves, get out the photosensitive resin and carefully fill the tank up to the arrow on the front.

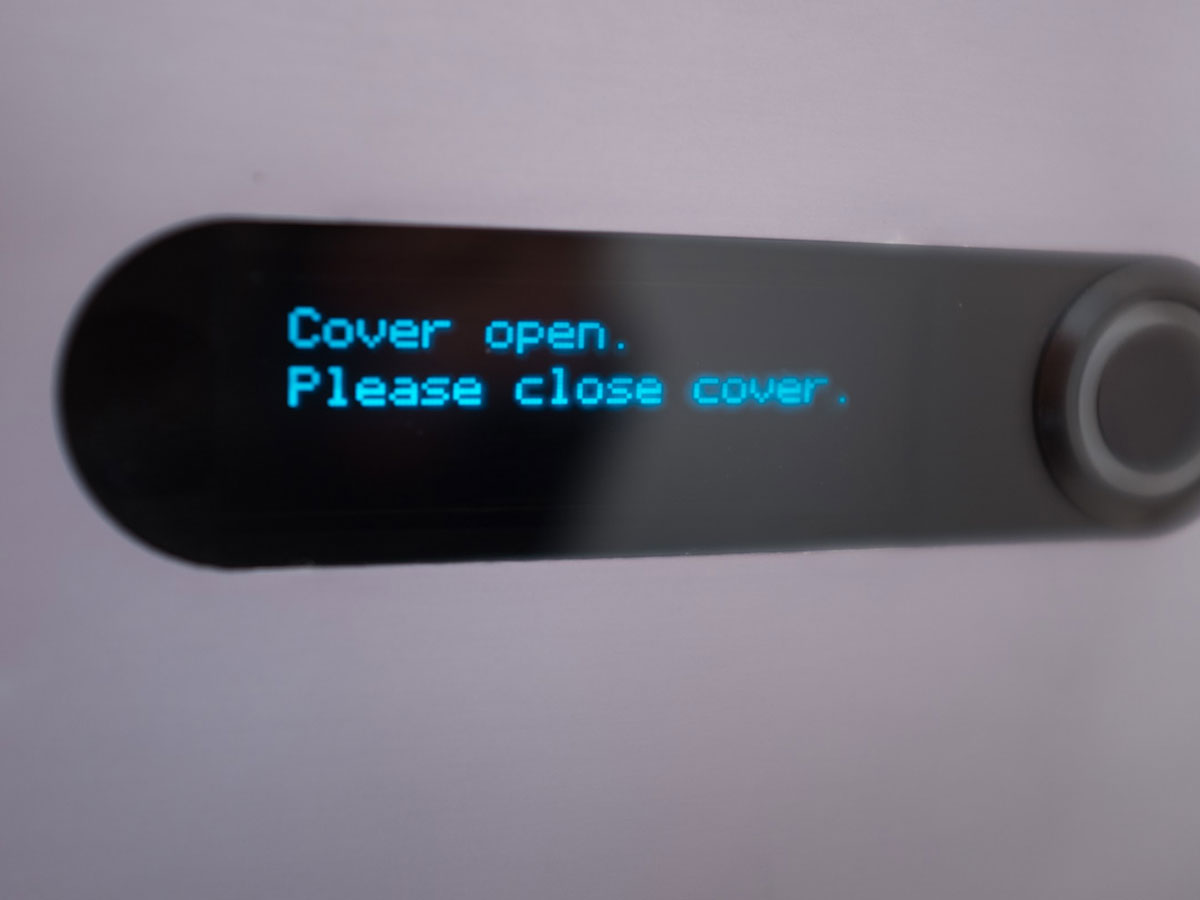

The Form 1+’s display will be urging you to close the cover – to prevent too much light falling on the resin which would cause it to harden prematurely. But before you close the lid you’ll need to attach the steel-faced build platform, which sits upside down over the resin tank, ready to plunge into the gooey liquid and get making.

Check this out › CES 2015: Stuff interviews Max Lobovsky, co-founder of Formlabs

Software

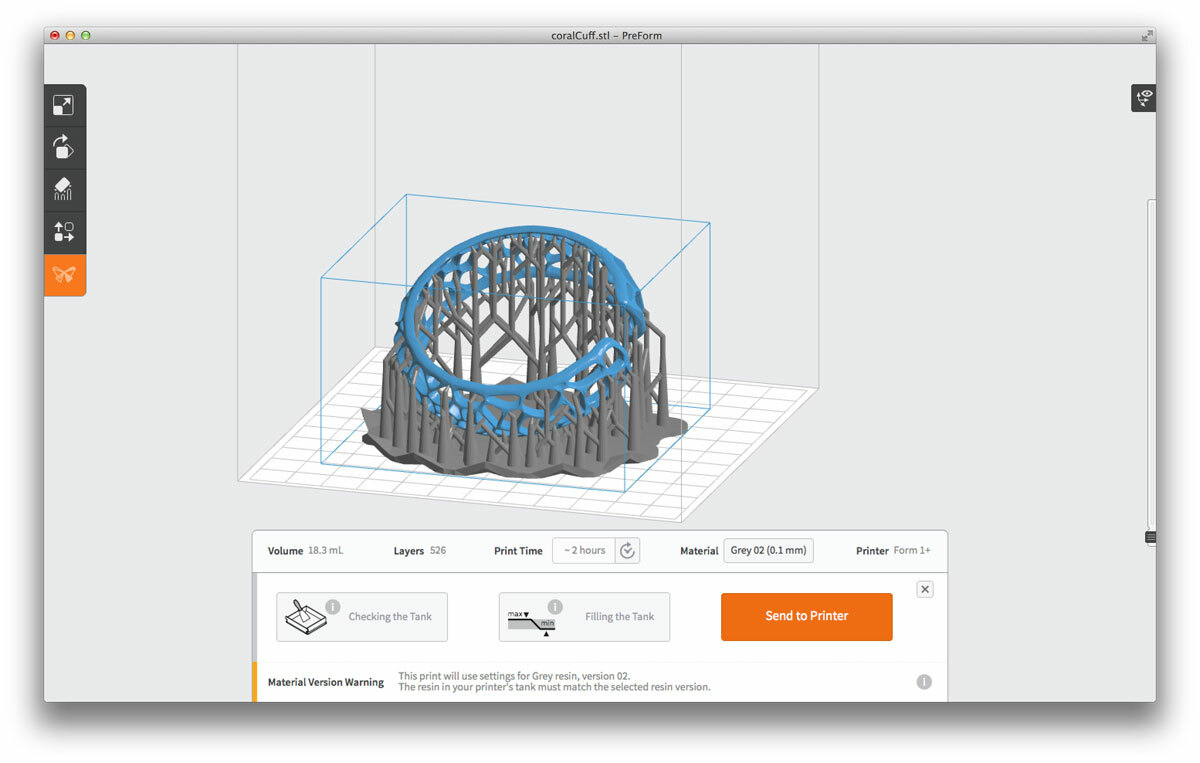

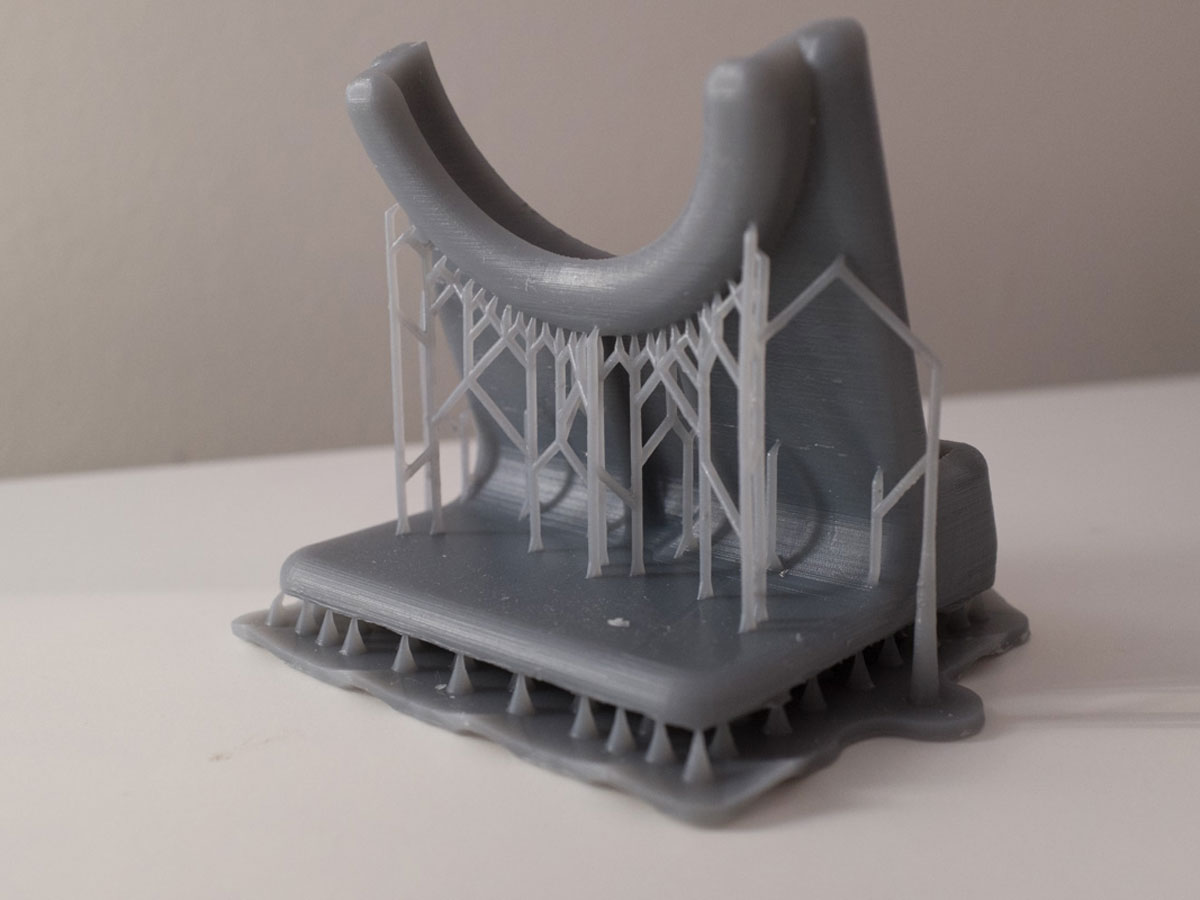

The PreForm software is very simple compared to FDM printers, partly because there are fewer parameters to adjust – no temperature, fans speed or infill density to tinker with. Simply load in your STL file, tell it which resin you’re using, choose a layer thickness between 0.025mm and 0.1mm (or 0.2mm for fastest printing only with the clear resin). From there you can auto-generate support material and get printing.

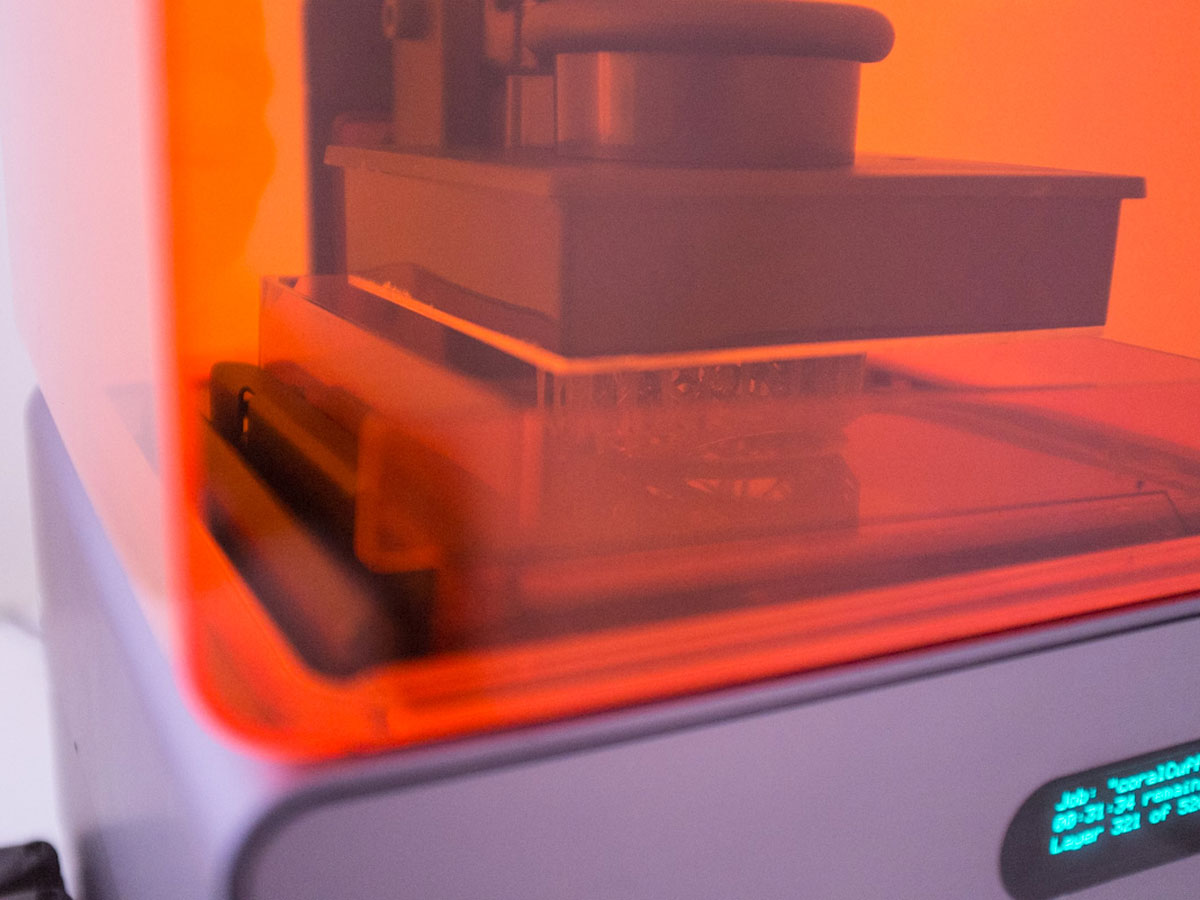

There’s only one control on the Form 1+ itself – a single button next to the bright, clear text-based LED display. It turns the machine on and off, starts printing, pauses it or even cancels it depending on the context of the display. When sending a print to the machine the display tells you how many layers have loaded (when they are all loaded you can detach your computer) and then how long until the print is finished.

Watching the Formlabs Form 1+ at work is mesmerising – a point of light flits underneath the resin around the base of the object being built, the resin tank tilts to move the resin around, then returns to its original position and the dance begins again.

Repeatable results

The whole process is a lot more predictable than FDM printing, and it is less of a worry leaving it running while you’re out or asleep than it is with FDM printers and all their heated parts. That’s not to say that it will produce flawless prints every time – there is still a learning process involved, which will likely include coming home to a half-built object dumped upside-down in the resin tank, surrounded by a hard mass of what it was trying to build stuck on the bottom.

But whereas with many FDM printers you might perform the same print twice with the same settings and get a perfectly-formed print one time and a curly mess of hot plastic the next, the Form 1+ brings consistency. For example, when a print has fallen off, increasing the point size of the supports (how thick the supports are where they attach to the print) will mean that your print won’t pull away from them and fall off so easily next time.

Read this › Geek Projects Special: 3D printing

Post-printing process

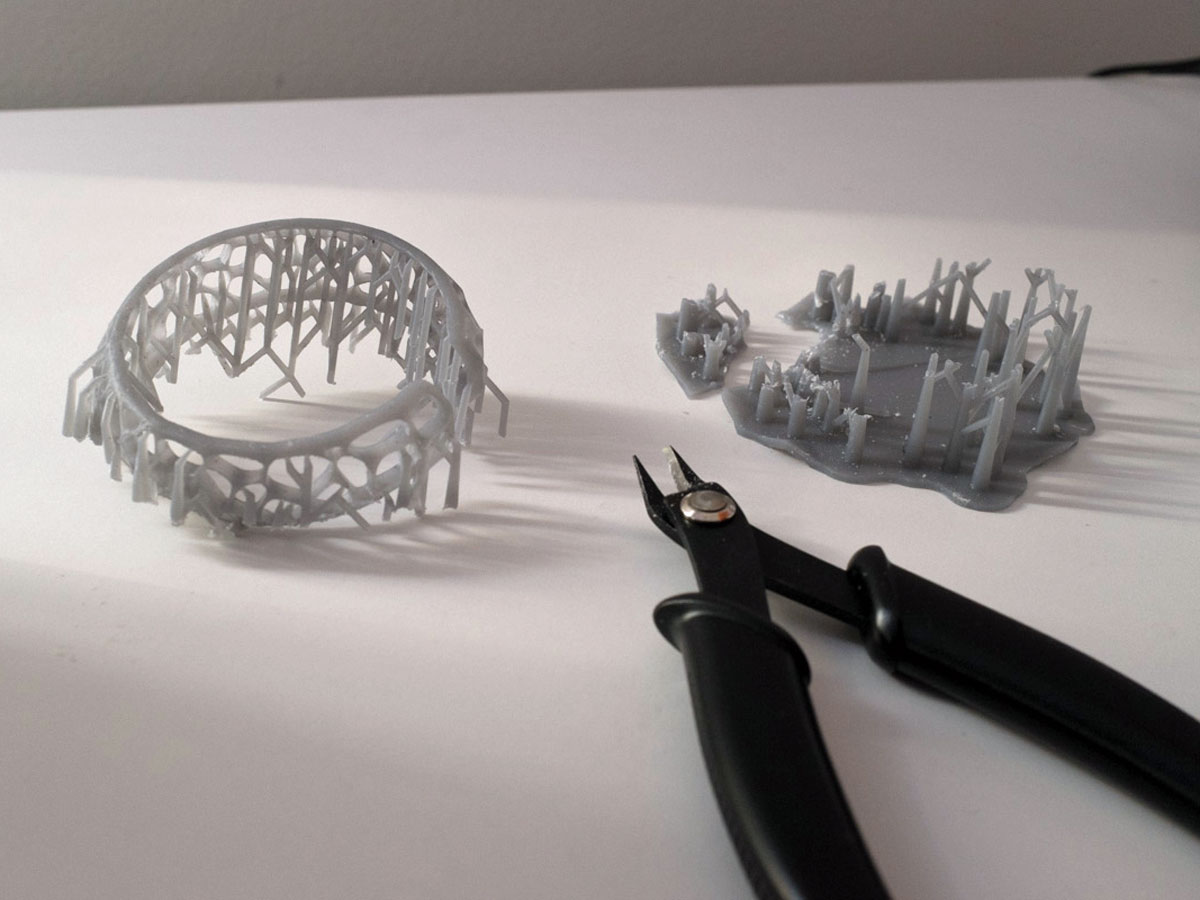

The Formlabs Form 1+ comes with a finish kit that includes two sealable plastic tubs, a scraper, tweezers, flush cutters, a cloth, two plastic tubs, a rinse basket, a squeezy bottle and a base to sit them and the build platform on. Once printing has finished you remove the build platform with the print attached, turn it over and put it on the finish kit base then attack it with the scraper.

Prising it off the steel plate is surprisingly difficult, and though the instructions warn against accidentally stabbing yourself with the scraper they don’t warn how sharp the edge of the platform itself is – we sliced a finger during this process.

Once loose you drop the print into the rinse basket in one of the tubs filled with isopropyl alcohol (which you’ll need to buy separately and seems pretty hard to find on the high street – Amazon can sort you out, though).

A couple of minutes of shaking, followed by a 10 minute soak and then repeating the process to give it a final rinse in the second tub should rid your print of any excess resin. Once it’s dried it’ll be ready for you to break off the supports and do any trimming with the cutters if necessary. The prints can be quite soft when they come out of the alcohol, can can be easily marked if handled while still wet.

Print quality

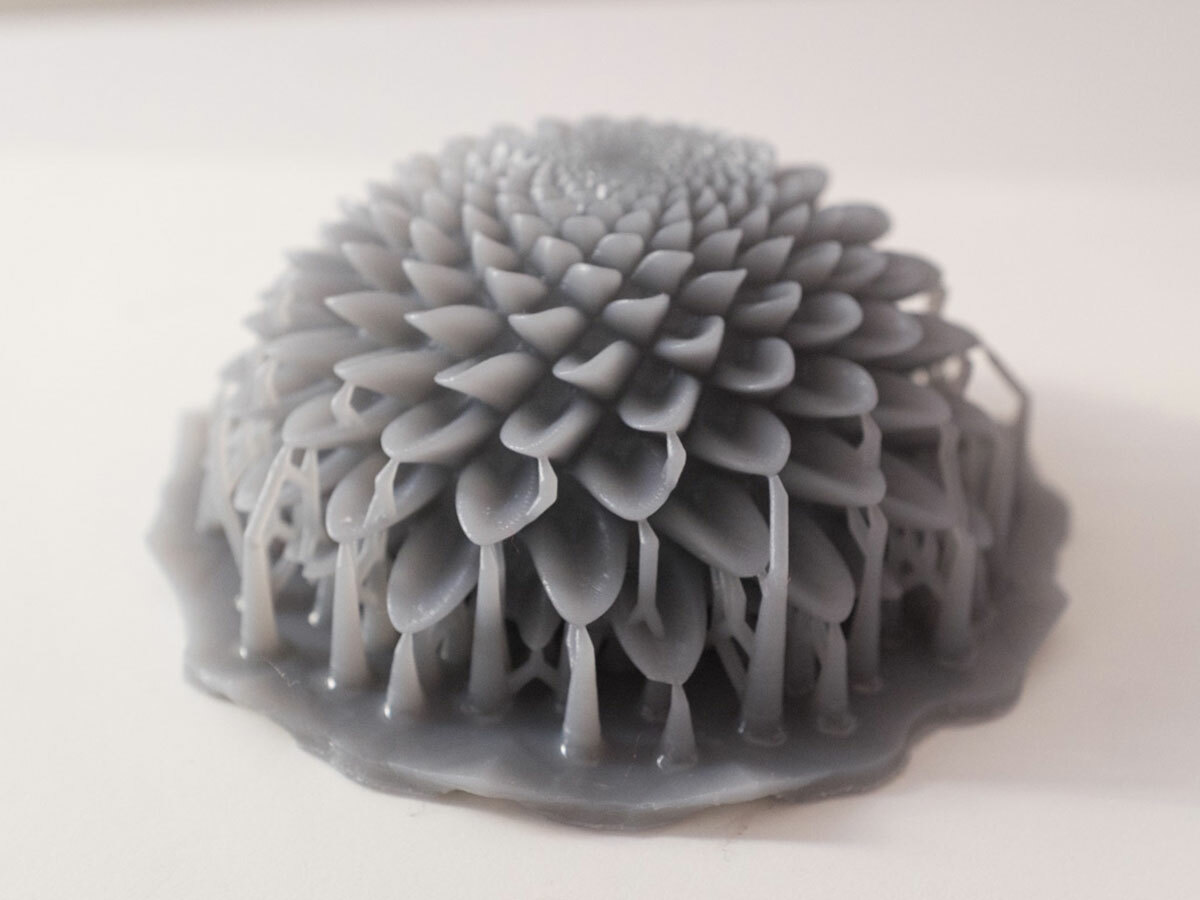

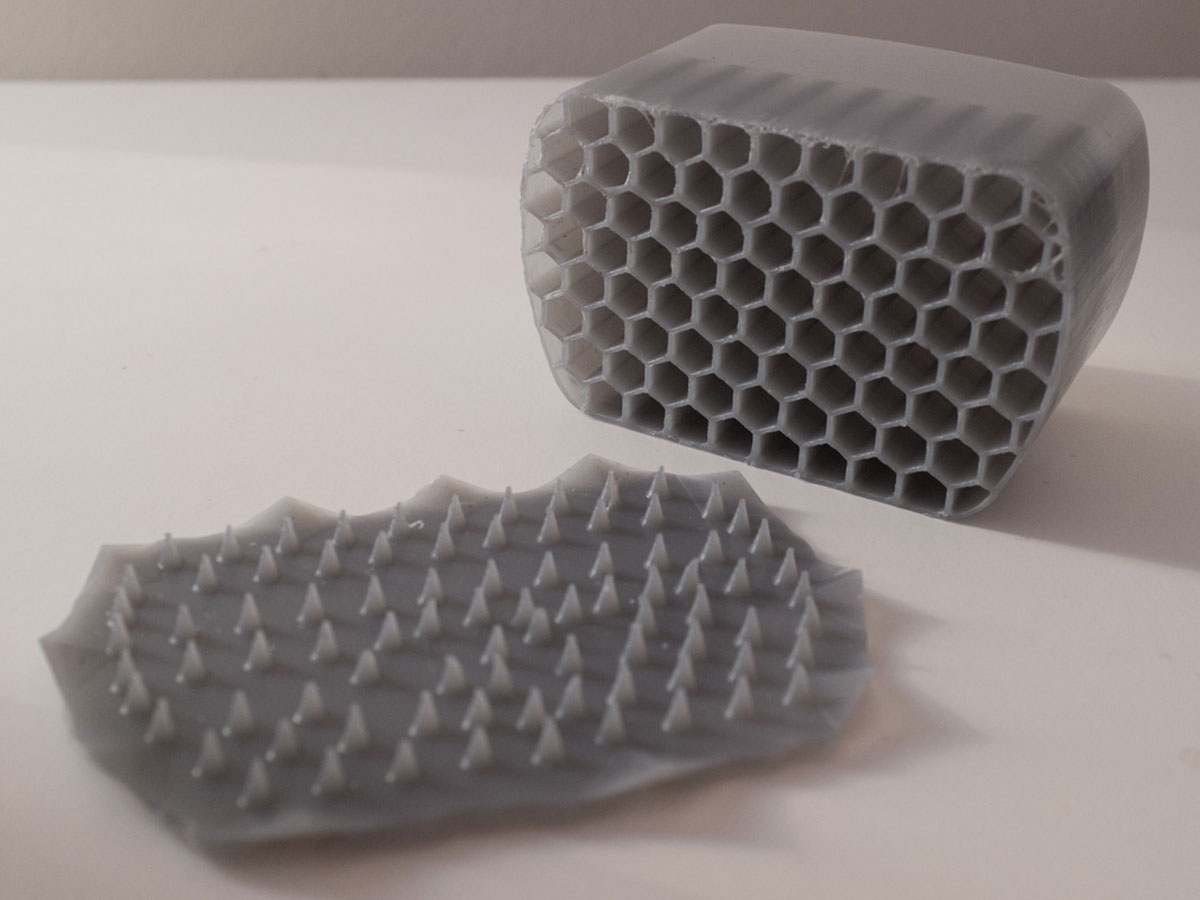

Prints from the Form 1+ display great detail and very even surface texture – none of the loops and burrs that can occur on FDM-printed models, though there may be the occasional bubble. Medium quality, 0.05mm layer models are actually quite difficult to tell apart from the finest 0.025mm layer models which take around twice as long. Our average print, which used around 30ml of resin, took between two and four hours, with the finish time predicted to the second and layer progress displayed on the front of the machine.

The SLA process has its quirks, one of which is that it struggles to print large flat surfaces when they’re parallel with the build plate, resulting in a bobbled, peeling finish. This is easily solved, however, by tilting your model to sit at around 45 degrees from the build platform surface when setting up the print.

Then there is the issue that when printing hollow enclosed shapes – a sphere, for example – uncured resin will be trapped inside. To avoid this you’ll need to add drain holes to allow the resin to escape. This can be done in your 3D modelling software of choice, which is also where you’ll need to hollow out models in the first place as while most FDM printer software will do this for you, Formlabs’ PreForm software will print a solid object whenever it can, using up valuable resin and taking longer to print.

Expensive hobby

The Formlabs Form 1+ is certainly capable of fantastic, consistent results – something that seems to have eluded FDM printers so far – but you will pay for the privilege.

While the €3000 asking price for the Form 1+ is at the very top end of what you could reasonably call a ‘consumer’ 3D printer, that’s not the only cost involved. You’ll also pay €135 per litre of resin, and then the tanks themselves are also consumables that Formlabs says will last for about two litres of resin each and cost €55 to replace. There’s also the isopropyl alcohol to keep topped up too, at about £20 for five litres.

You’ll get a bottle of resin and a build tank with the Form 1+, so at least you’ll be able to hone your techniques and success rate with this before you start buying more yourself. Third party resins are also available, such as MakerJuice (£39/500ml, imakr.com). But there’s no denying that you’ve got to be pretty committed to take the financial plunge.

Formlabs Form 1+ tech specs

Layer thickness: 25-200 microns (0.025 – 0.2mm)

Build volume: 125×125×165mm

Interface: USB

Dimensions: 30×28×45cm

Weight: 8kg

Formlabs Form 1+ verdict

I’ve tested a whole bunch of 3D printers over the last year or so, and the Formlabs Form 1+ is a real step forward, giving confidence in the process and real conviction in the results achievable.

The level of detail and finish it can achieve is stunning – and it’s a great looking machine too. It’s the 3D printer we’d choose for our own use, but the high purchase price and ongoing running costs mean it’s difficult to justify buying if you don’t use it as part of a money-making business.

You could always come up with a money making scheme in order to justify an expensive 3D printing hobby, of course. I’m certainly trying to come up with one.

Stuff Says…

A beautiful machine that produces stunning, predictable results – but the price is very high for the average 3D printing hobbyist

Good Stuff

Brilliantly predictable prints

Variety of materials available

Speed of printing

Bad Stuff

Expensive

Need extra software to hollow out models